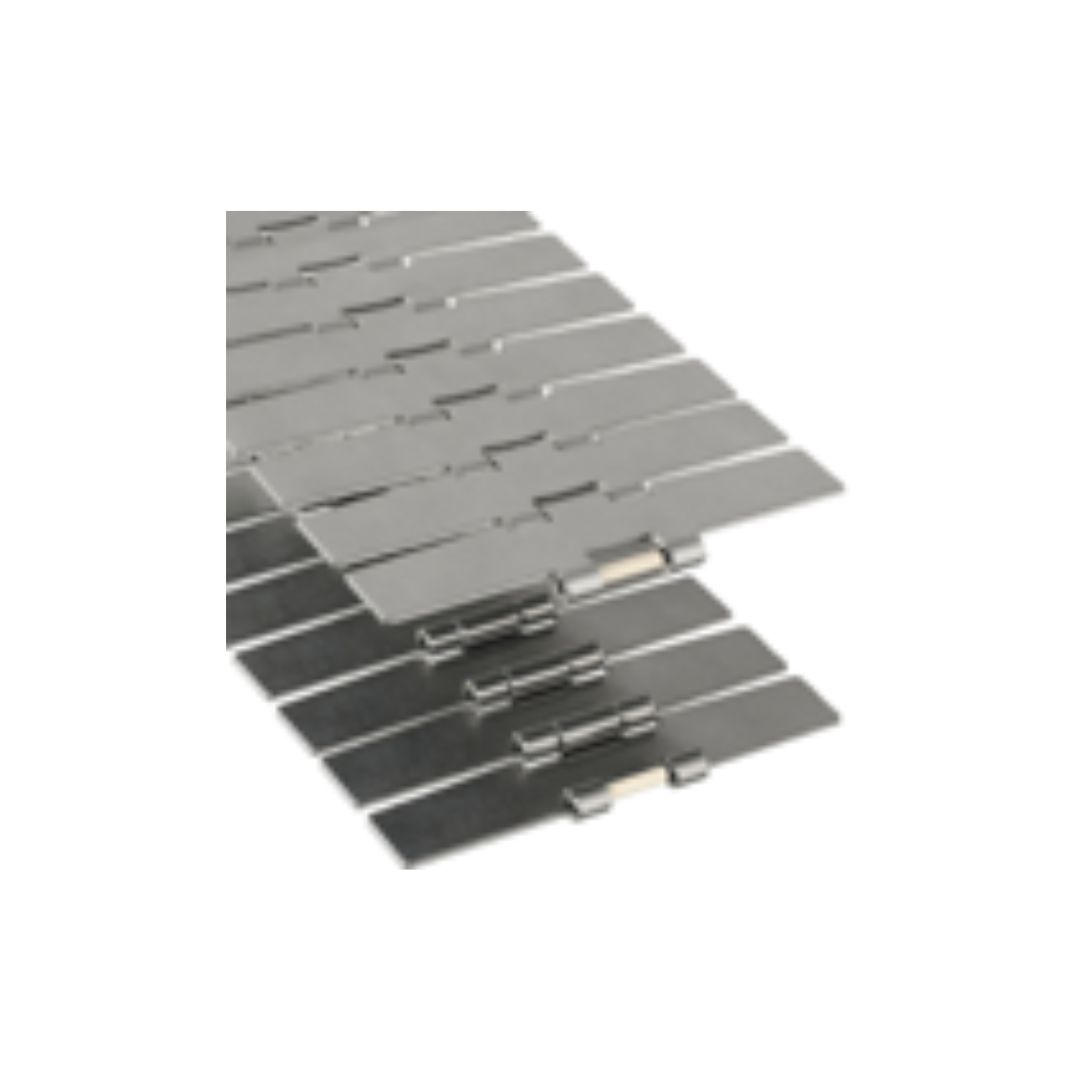

Modular chain

Modular Chain is a type of plastic or stainless-steel modular conveyor chain that is widely used in the food, beverage industry, pharmaceuticals, and chemicals. It is made up of interlocking plastic modules that are linked together using hinge pins or other types of connectors.

The modules used in Modular Chain are made from a high-quality plastic and stainless-steel material that is resistant to wear and tear and can withstand high temperatures and chemicals. The chain is designed to be self-supporting and can be configured in a variety of shapes and sizes to meet specific requirements.

One advantage of Modular Chain is its flexibility and durability. It can be easily customized to meet specific requirements, with different module sizes and shapes available to accommodate a wide range of products. It can also be configured to operate in a variety of environments, including harsh or corrosive conditions, It can withstand harsh environments and extreme temperatures.

Modular Chain is also highly durable and requires minimal maintenance. It is designed to be easily cleaned and can withstand high-pressure cleaning without damage. The chain can be easily disassembled for cleaning ormaintenance, and the modules can be replaced individually if damaged or worn.

Another advantage of Modular Chain is its ease of installation. The chain is designed to be easily assembled and disassembled, allowing for quick and easy installation or customization. The chain can be easily connected to other conveyor components, such as sprockets or drive units, to create a complete conveyor system.

Overall, Modular Chain is a versatile and efficient conveyor chain used in the food and beverage industry. It provides flexibility, durability, and ease of maintenance, making it an essential tool for any industry that requires the efficient movement of products or materials.

Technical description:

Module Material: The modules are typically made from a high-quality plastic material and high-quality stainless steel, such as acetal, polypropylene or polyethylene. The material used is resistant to wear and tear and can withstand high temperatures and chemicals.

Module Design: The modules used in Modular Chain are designed to be self- supporting, with a variety of sizes and shapes available to accommodate different products or materials. The modules are linked together using hinge pins or other types of connectors, allowing for flexibility in the configuration of the chain.

Chain Pitch: The chain pitch of Modular Chain can vary depending on the specific application, with pitches ranging from 1.5 inches to 4 inches. The pitch is determined by the size of the modules used and the load capacity of the chain.

Load Capacity: Modular Chain is available in a range of load capacities, from light-duty chains used for small products to heavy-duty chains used for large, heavy items. The load capacity is determined by the size and strength of the modules and the connectors used to link them together.

Environmental Considerations: Modular Chain may be used in a variety of environments, including harsh or corrosive conditions. In these cases, the chain must be designed to withstand the environmental conditions and may require additional components such as protective coatings or specialized materials.

Ease of Maintenance: Modular Chain is designed to be easily assembled and disassembled, allowing for quick and easy maintenance or customization. The modules can be easily replaced if damaged or worn, and the chain can be cleaned easily with no need for specialized cleaning equipment.

Overall, Modular Chain is a highly versatile and efficient conveyor chain used in a wide range of industries, particularly the food, beverage, pharmaceuticals, and chemicals industries. It is available in a variety of load capacities, chain pitches, and environmental conditions, and provides flexibility, durability, and ease of maintenance.