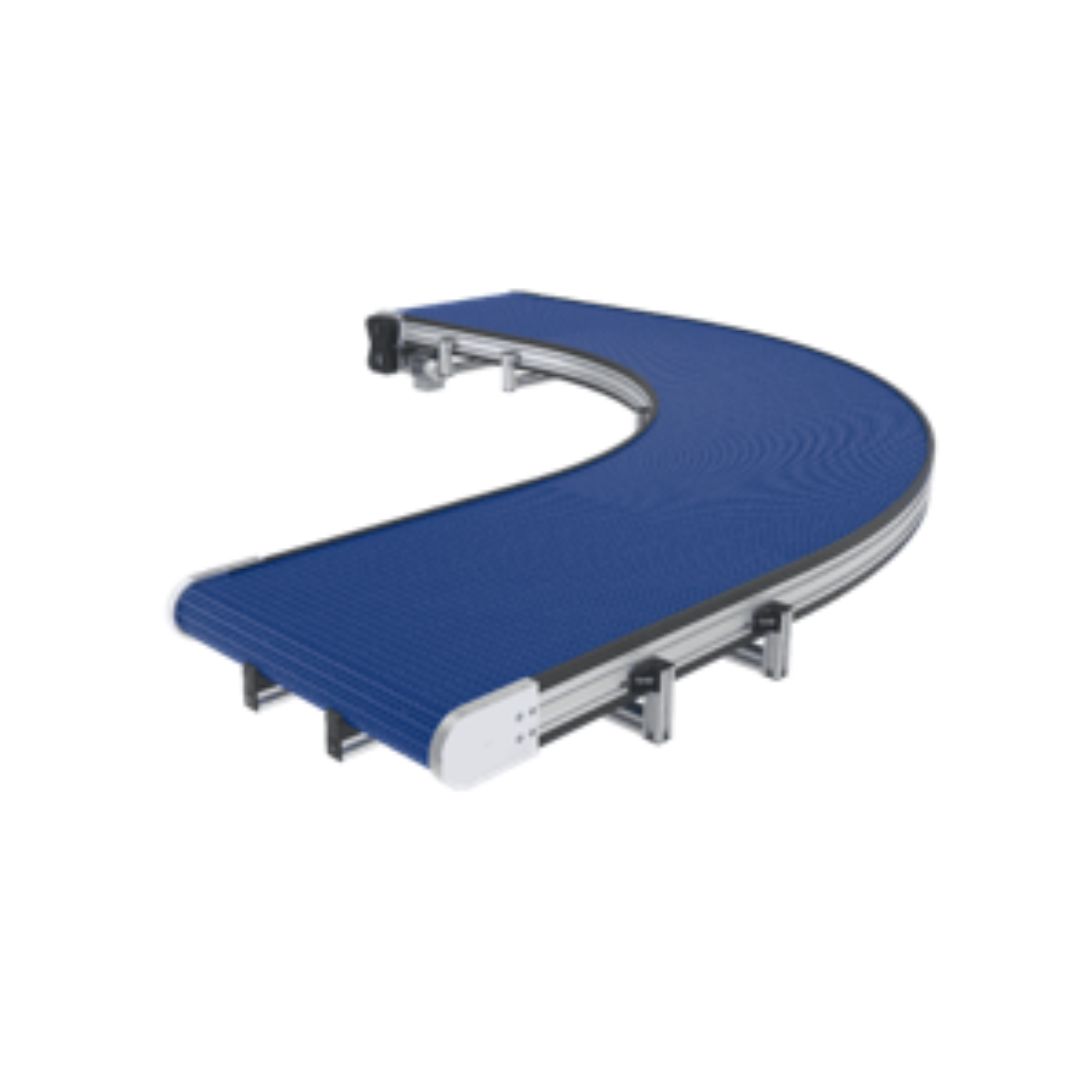

Modular Belt Conveyor

Description

Modular belts are a type of conveyor belt made up of interlocking plastic or metal modules. These modules are designed to be easily assembled and disassembled, allowing for quick and easy maintenance and customization.

The modular belt consists of a series of modules that are linked together using hinge rods or other types of connectors. The modules are designed to be self-supporting and can be configured in a variety of shapes and sizes to meet specific requirements.

Modular belts are widely used in the food and beverage industry, where they are used to transport products through processing and packaging lines. They are also used in other industries, such as automotive, pharmaceuticals, and logistics, where they provide a reliable and efficient material handling solution.

One advantage of modular belts is their flexibility. They can be easily customized to meet specific requirements, with different module sizes and shapes available to accommodate a wide range of products. They can also be configured to operate in a variety of environments, including harsh or corrosive conditions.

Modular belts are also highly durable and require minimal maintenance. They are made from materials such as polypropylene, polyethylene, or stainless steel, which are resistant to wear and tear and can withstand high temperatures and chemicals.

Another advantage of modular belts is their ease of installation and cleaning. The modules can be easily assembled and disassembled, allowing for quick and easy maintenance or customization. They can also be cleaned easily, with no need for specialized cleaning equipment.Overall, modular belts are a versatile and efficient material handling solution used in a variety of industries. They provide flexibility, durability, and ease of maintenance, making them an essential tool for any industry that requires the efficient movement of products or materials.

Technical Description:

Module Material: Modular belts are typically made from plastic, such as polypropylene or polyethylene, or metal, such as stainless steel. The material used will depend on the specific application, with plastic modules being used for lighter loads and metal modules being used for heavier loads or harsher environments.

Module Design: The modules used in modular belts are typically designed to be self-supporting, with a variety of sizes and shapes available to accommodate different products or materials. The modules are linked together using hinge rods or other types of connectors, allowing for flexibility in the configuration of the belt.

Belt Width: The width of a modular belt can vary depending on the specific application, with widths ranging from a few inches to several feet. The width is determined by the size of the modules used and the load capacity of the belt.

Load Capacity: Modular belts are available in a range of load capacities, from light-duty belts used for small products to heavy-duty belts used for large, heavy items. The load capacity is determined by the size and strength of the modules and the connectors used to link them together.

Environmental Considerations: Modular belts may be used in a variety of environments, including harsh or corrosive conditions. In these cases, the belt must be designed to withstand the environmental conditions and may require additional components such as protective coatings or specialized materials.

Ease of Maintenance: Modular belts are designed to be easily assembled and disassembled, allowing for quick and easy maintenance or customization. The modules can be easily replaced if damaged or worn, and the belt can be cleaned easily with no need for specialized cleaning equipment.

Overall, modular belts are a highly versatile and efficient material handling solution used in a wide range of industries. They are available in a variety of load capacities, widths, and environmental conditions, and provide flexibility, durability, and ease of maintenance.