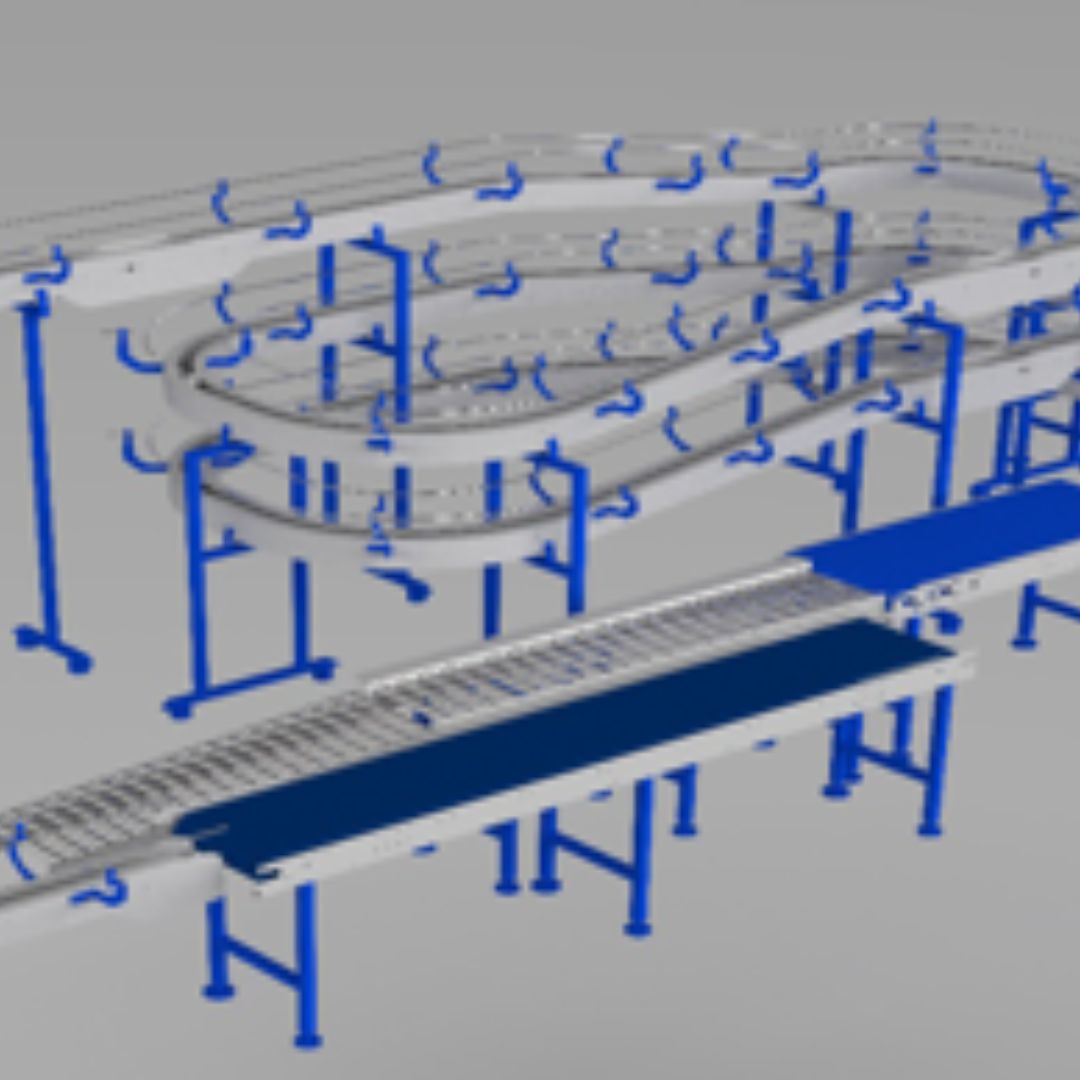

Alpine conveyor

Description:

conveyor system used to transport materials or products from one level to another within a building or facility.

The conveyor consists of a continuous belt, typically made of plastic or metal, that is driven by a motor and guided along a spiral or helical path. The belt is supported by a series of rollers, which are mounted on a central shaft that rotates along with the belt.

Alpine conveyors are often used in applications where space is limited, as they can transport materials vertically without taking up a significant amount of floor space. They are also useful for moving materials between multiple levels in a building, such as in a warehouse or manufacturing facility.

The design of alpine conveyors allows for a smooth, continuous flow of materials, with minimal impact or damage to the products being transported. They are commonly used for items such as packages, boxes, and cartons, but can also be used for other materials such as liquids, powders, or granular materials.

Overall, alpine conveyors offer a versatile and efficient solution for vertical transportation of materials in a variety of industries.

Technical details:

Alpine conveyors have several technical details that are important to consider when selecting and using them. Here are some of the key technical details:

Capacity: The capacity of an alpine conveyor is the maximum weight or volume of material that it can handle. This is determined by factors such as the size and strength of the belt, the diameter of the central shaft, and the motor power.

Speed: The speed of an alpine conveyor is the rate at which the belt travels along the spiral path. This is typically measured in feet per minute (or meters per minute) and can be adjusted to suit the specific needs of the application.

Size and dimensions: Alpine conveyors come in a range of sizes and dimensions, depending on the specific requirements of the application. The height, width, and length of the conveyor can all vary, as can the diameter of the central shaft and the size of the rollers.

Material and construction: The belt and other components of an alpine conveyor can be made from a variety of materials, depending on the needs of the application. For example, the belt might be made from plastic, metal, or rubber, and the rollers might be made from steel, aluminum, or plastic.

Power supply: Alpine conveyors typically require an electrical power supply to operate the motor that drives the belt. The voltage, phase, and frequency of the power supply can all vary depending on the specific needs of the application.

Control system: Alpine conveyors can be controlled using a range of systems, from simple manual controls to more complex automated systems. The control system can be used to adjust the speed and direction of the conveyor, as well as to monitor and control other aspects of the process, such as material flow and product quality.